![]()

We recognize that conservation of the global environment is the curcial agenda for all living things on the earth. We will participate actively in Environmental Preservation and set our idea as, “We will contribute to society through sound business activity and offering products which will satisfy our customers.”

Policy of Environment

TOYO BODY Co., Ltd. operates based on the following policy toward the realization of our environment ideal in our all business activities of development, production, and sales of truck rear body shells and their associated parts, transportation equipment parts, as well as our products and services.

- Evaluate environment effects concerning environmental aspects necessary for promotion business activities of the environment management system, products, and services, and set environmental purposes and targets concerning reduction of environment load, compliance with regulations, and prevention of pollution. Implement promotion activities in accordance with our environment management system, drive the PDCA cycle, and provide ongoing improvement.

- Offer environment-friendly products and services, and reduce environment load in business activities

recognize limitedness of the global environment and resources, and pursue the following:- Provide products and services that can help reduce environment load throughout lifecycle.

- Strive to maintain the corporate culture that values the environment.

- Promote resource saving and energy saving activities.

- iPromote activities to prevent global warming.

- Work on reduction of waste.

- Operate while driving harmony between the environment and the economy.

- Comply with the regulations concerning environment, as well as other requirements we agree on.

- We work on the activities described above with company-wide efforts.

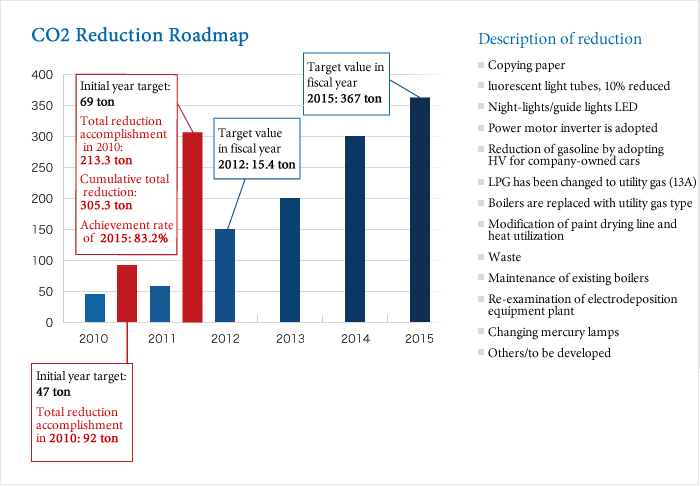

CO2Reduction Roadmap

TOYO BODY Co., Ltd. has created a CO2reduction roadmap and has been implementing every operations improvement.

Effects from the pursuits

- Reduction of fluorescent lighting and adoption of LED

Result: reduction of 6t of CO2 annually - Reduction from machine power/replacing with energy saving automatic vending machines

Result: reduction of 62.526kg of CO2 annually - Reduction of operating time of chillers (water cooling/heating appliances) and pressing machines

Result: reduction of 331.529kg of CO2 annually - Reduction of compressor discharge pressure

Result: reduction of 16.305kg of CO2 annually - Introduction of power motor inverter

Result: reduction of 36t of CO2 annually - Installation of paint drying furnace outlet door

Result: reduction of 6.8t of CO2 annually

We have realize lightness of bodies

he drinking water truck we developed in 2007 achieved 751 kg, which was approximately 20% lighter than the existing type. Because of this, even when 2 ton freight is loaded, the total weight of a vehicle does not exceed 5 ton, allowing transportation with a regular driver’s license.

The drinking water truck we developed in 2007 achieved 751 kg, which was approximately 20% lighter than the existing type. Because of this, even when 2 ton freight is loaded, the total weight of a vehicle does not exceed 5 ton, allowing transportation with a regular driver’s license.

Report on our environmental practice

Report on our environmental practice Revised on November 7, 2010 (PDF file /925KB)